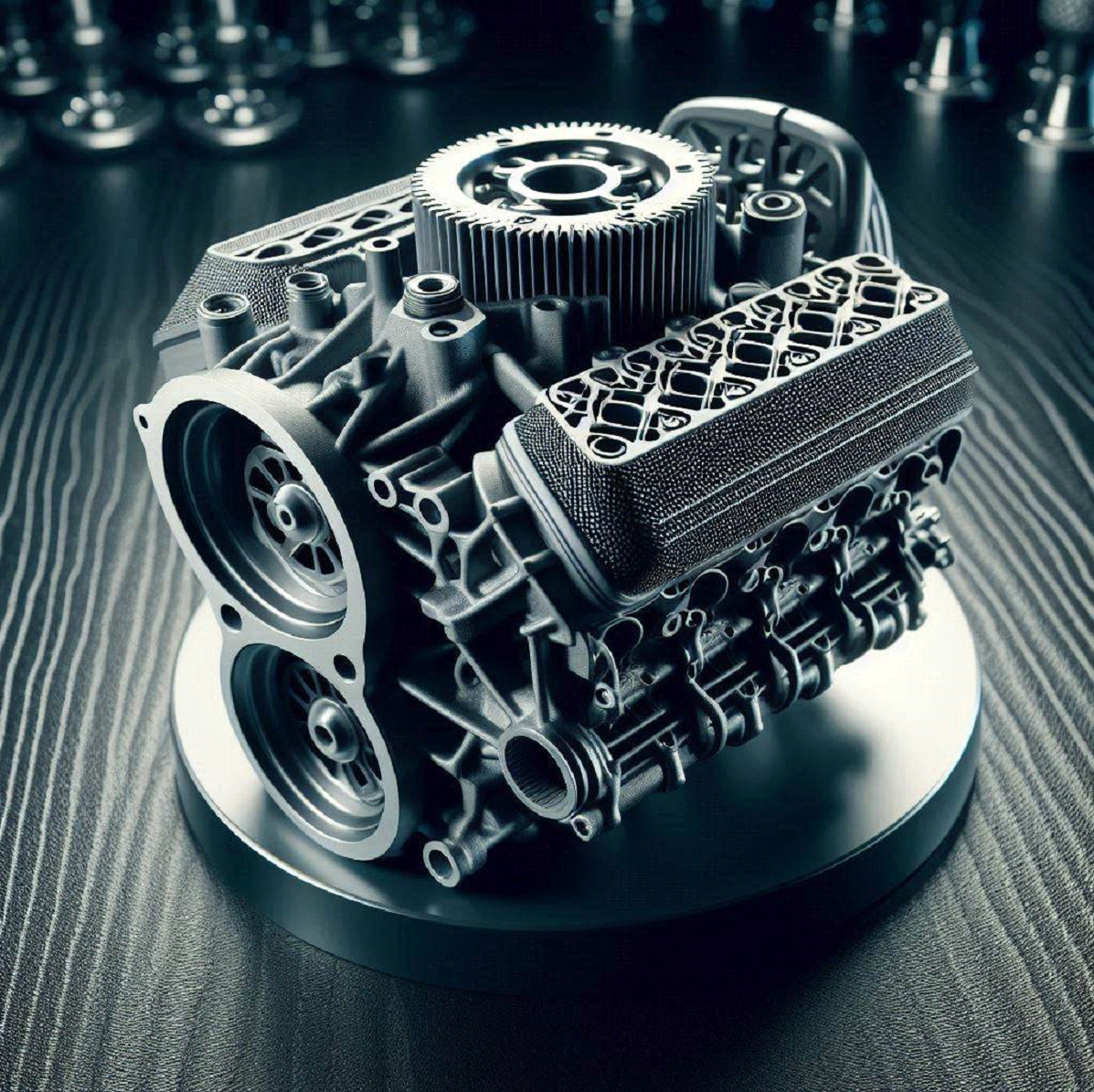

3D Printed Engine Parts

3D Printing is revolutionizing manufacturing. Moreover, it offers numerous benefits for the production of engine components and vehicle parts. Here’s how it addresses the areas you mentioned

Image Courtesy: Bing Image Creator Microsoft Designer

Benefits of 3D Printing in Automotive Parts

Adaptable Design: 3D printing offers the ability to produce complex shapes and detailed designs that traditional manufacturing techniques find challenging or unachievable, showcasing its design versatility.

Rapid prototyping: 3D printing enables quick iteration and refinement of designs, accelerating product development cycles3.

Customization: Parts can be easily customized to specific needs or applications, catering to personalization demands5.

Weight reduction: Topology optimization and lattice structures made possible by 3D printing result in lighter yet stronger parts, improving vehicle efficiency23.

Image Courtesy: Bing Image Creator Microsoft Designer

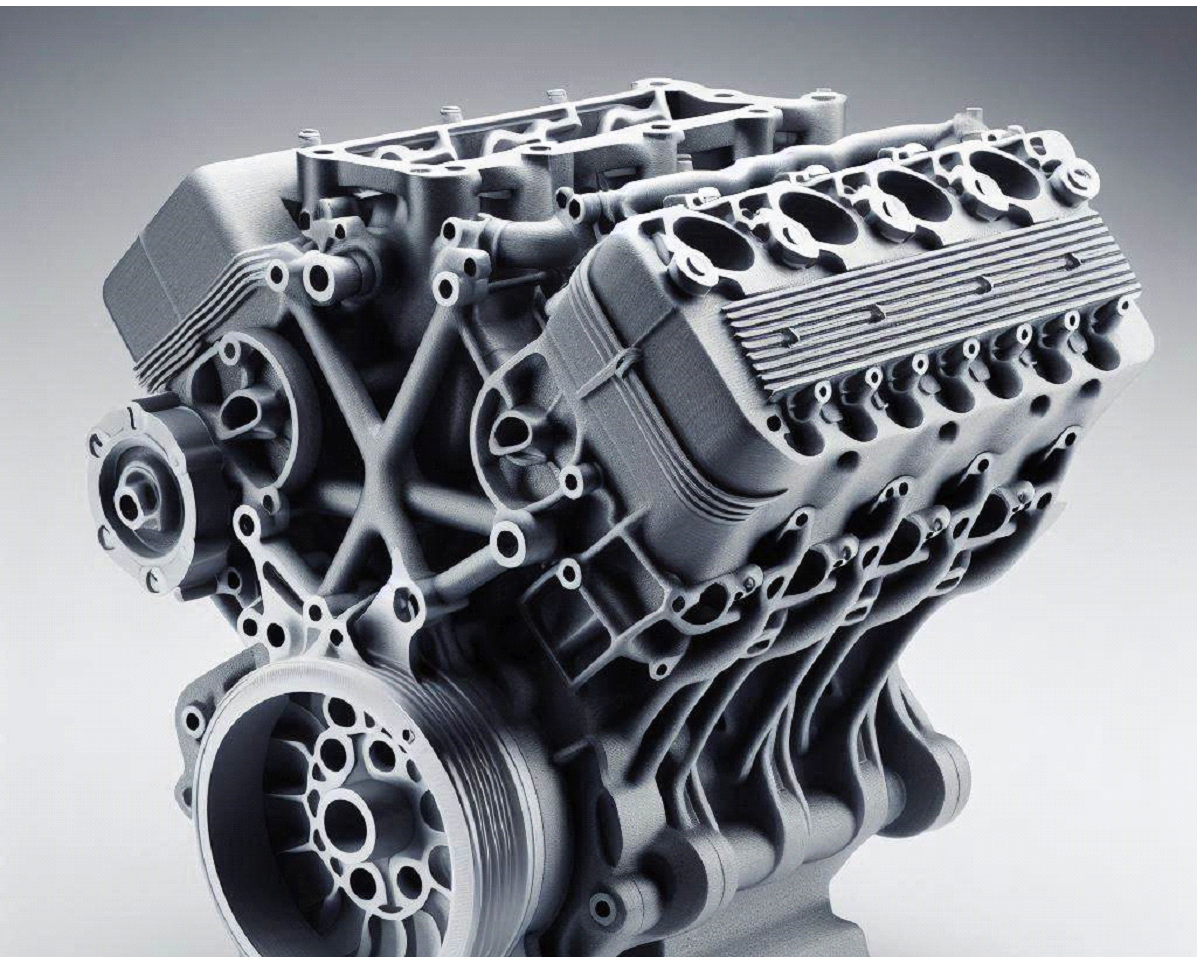

Purpose of Using 3D Printers for Engine Components

3D printing is used for engine components to produce complex geometries like internal cooling channels, thin walls, and fine meshes that enhance performance3.

It allows for quick creation and evaluation of new designs, which decreases both the time and expenses associated with development.

Additionally, it allows for the production of lightweight yet durable parts, leading to improved engine efficiency2.

Image Courtesy: Bing Image Creator Microsoft Designer

3D Printing for End-Use Parts in Transportation

The transportation sector is making greater use of 3D printing for manufacturing final components.

Companies like BMW, Porsche, and Ford already use 3D-printed parts in production vehicles23.

Examples include Bugatti’s 3D-printed titanium brake calipers and Ford’s 3D-printed cylinder head for their V8 engine2.

Image Courtesy: Bing Image Creator Microsoft Designer

Weight Reduction and Vehicle Efficiency

The creation of lightweight components is made possible through 3D printing by applying topology optimization and lattice designs, resulting in reduced weight.

For instance, Porsche used 3D printing to create lightweight pistons for their 911 GT2 RS, achieving a 10% weight reduction and increased engine efficiency2.

Image Courtesy: Bing Image Creator Microsoft Designer

Impact on Vehicle Parts Supply Chain and Logistics

3D printing can significantly reduce shipping costs and lead times by enabling on-demand, localized production of parts1.

This minimizes the need for transportation from remote locations and reduces reliance on external suppliers1.

Furthermore, it removes the necessity for costly tooling, thereby simplifying the supply chain even more.

Image Courtesy: Bing Image Creator Microsoft Designer

3D Printing for Heavy-Duty Truck Parts

3D printing can be utilized for heavy-duty truck parts. Companies like Peterbilt Truck Parts & Equipment have reported up to 20% time savings by using 3D printing to visualize digital wiring diagrams on physical vehicles5.

The technology can produce replacement parts on demand, reducing downtime and inventory costs1. In summary, 3D printing offers numerous benefits for the automotive industry, from design flexibility and rapid prototyping to weight reduction and supply chain optimization.

It is increasingly being adopted for end-use parts production, revolutionizing how vehicles are developed and manufactured235.

3D Printed Engine Parts

3-D printing capabilities redefine visual 3D presentations. From Sci-Fi to Reality: 3-D is revolutionizing manufacturing. Explore the stunning Innovations in 3-D Printing markets.

Augmented Reality AR

We combine real-world and computer-generated content! Augmented Reality is paving the way for a new era of innovation. Join the AR digital revolution, enhancing customer experiences to revolutionizing employee training.

Product Displays

We provide various product displays, from small Point-of-Purchase to Major Trade Show Product Displays and unique Museum exhibit working modules. Furthermore, TECHCOM offers the best cutaways in the business. For example, our working Model Simulations show off your product and visually represent what is inside. Again, our training aid products are great for classroom teaching, training, or informative demos on the tradeshow floor.

Multi-Media

Highlight your products with powerful visual presentations for marketing, training, and trade shows. Moreover, our Computer Visualization takes your video, print, or media campaign to the next level. In addition, our Interactive services and Virtual Training bring your instructional programs to life. We also provide scriptwriting, graphics, and translation services. Above all, with our computer visualization and training expertise, we offer multiple solutions for your simulation needs.

Publications

Let us interpret complex technology and concepts for your audience with exceptional Technical writing and technical graphics services for print and digital technical publications. Moreover, our technical writers craft basic technical information into helpful print and digital publications.

In addition, TECHCOM has created tens of thousands of illustrations and graphics to demonstrate various components and concepts—for instance, visual representation of internal wiring and electrical systems. Also see Technical Publication Markets.

Be sure to follow us for updates on social media on Facebook, Twitter, and Linkedin.