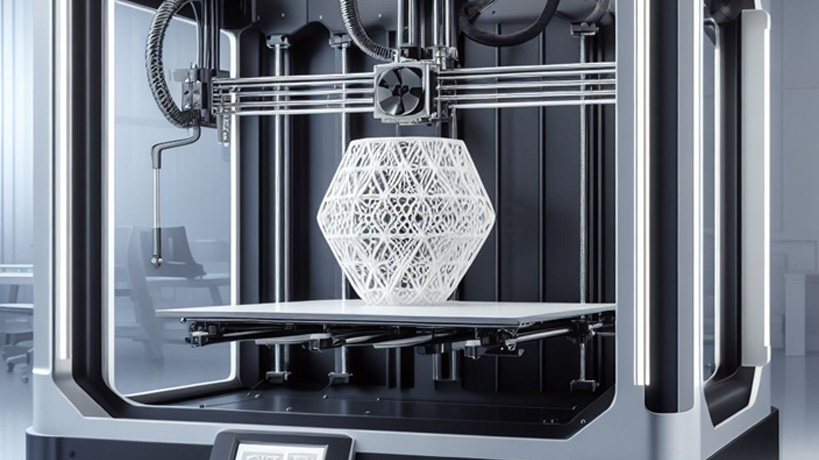

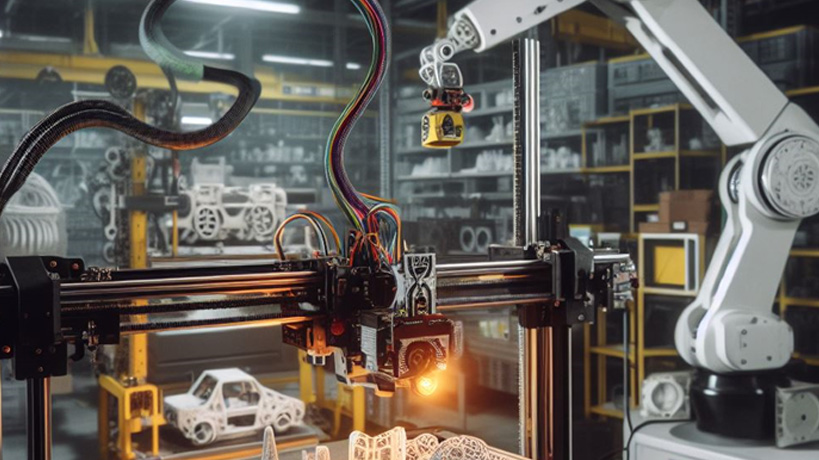

3D printing, also known as additive manufacturing, signifies a revolutionary change in the way products are designed and made. Unlike traditional methods such as subtractive manufacturing, which involve removing material from a solid piece to shape an object, this cutting-edge approach builds items layer by layer. In contrast, 3D printing constructs items by sequentially layering material until the desired form is complete. Consequently, this distinctive approach provides numerous advantages, such as:

- Design freedom: Creation of complex, detailed shapes that are impossible to produce using traditional methods.

- Reduced waste: Uses only the material required to create the object, minimizing waste and material costs.

- Cost-effectiveness: Increasingly cost-effective, making it a viable option for various manufacturing applications.

- Rapid prototyping: 3D printing enables rapid prototyping, allowing for faster product development cycles.

- Customization: 3D printing technology makes it possible to produce custom products, therefore meeting the specific needs of individual customers.

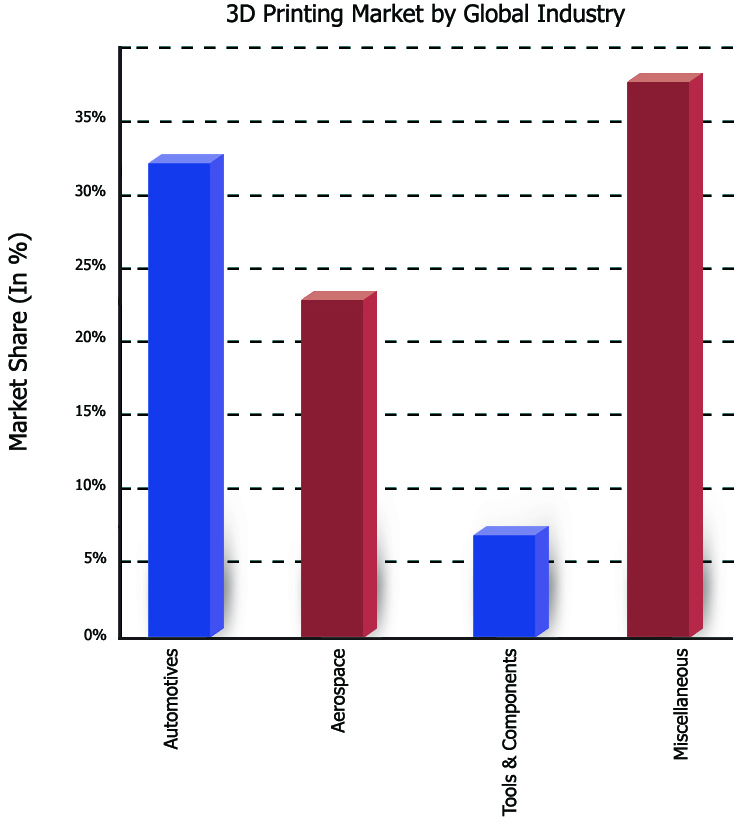

As a result of these growth areas and advantages, 3D printing is being adopted by a growing number of industries, including:

Aerospace 3D Printing

Automotive 3D Printing

Medical 3D Printing

Consumer Products 3D Printing

Industrial Tooling 3D Printing

Automotive 3D Printing

Automotive engineers are also using 3D printing technology to produce a variety of parts, including:

- Prototypes: Prototypes of new car parts. Moreover, it allows for faster and more affordable testing.

- Custom parts: Car parts, such as interior trim and exterior panels.

- Performance parts: 3D printed Transmissions, Car performance parts, such as engine components and aerodynamic body panels.

Aerospace 3D Printing

The aerospace sector was among the first to embrace 3D printing technology.

More importantly, this technology is being used to produce a wide range of aerospace parts, including:

- Aircraft components: This technique makes aircraft lighter and more robust than traditionally manufactured parts, thus improving fuel efficiency and performance.

- Rocket engines: Complex rocket engine parts that are difficult to create using old-style methods are produced.

- Satellite components: As a result, 3D-printed satellite components can be made lighter and more compact, reducing launch costs.

Medical 3D Printing

In the medical field, 3D printing is having a substantial impact on the medical industry. Consequently, this technology is now employed in creating numerous medical devices, such as:

- Implants: Implants can be customized to fit the specific needs of individual patients.

- Prosthetics: The production of prosthetic limbs has become more affordable and comfortable.

- Surgical tools: Surgical instruments that are more precise and effective.

Consumer Products 3D Printing

3D printing produces a growing number of consumer products. The 3D manufacturing process allows businesses to design, customize, and produce consumer goods more efficiently and cost-effectively. For example, 3D prototyping and manufacturing include:

- Jewelry: Custom jewelry designs.

- Toys: Personalized toys and games.

- Home décor: Unique and customized home décor items.

- Marketing: Promotional products.

- Communication: Signs and Lettering.

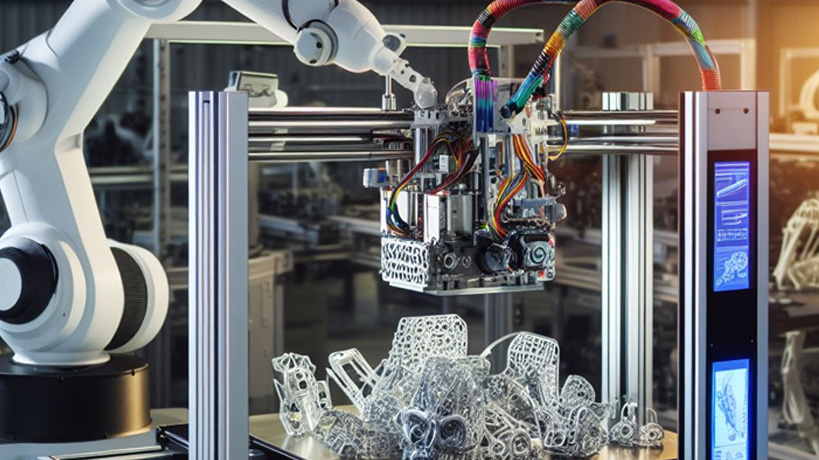

Industrial Tooling 3D Printing

3D printing creates industrial tooling that is lighter, stronger, and more durable than traditionally manufactured tooling. More importantly, it helps improve manufacturing processes’ efficiency and productivity.

Conclusion

3D printing is revolutionizing manufacturing across a wide range of industries. Moreover, as the technology continues to develop, expect to see more innovative applications for 3D printing in the years to come.

ABOUT TECHCOM

3D Printing

3-D printing capabilities redefine visual 3D presentations. From Sci-Fi to Reality: 3-D is revolutionizing manufacturing. Explore the stunning Innovations in 3-D Printing markets.

Augmented Reality AR

We combine real-world and computer-generated content! Augmented Reality is paving the way for a new era of innovation. Join the AR digital revolution, enhancing customer experiences to revolutionizing employee training.

Product Displays

We provide various product displays, from small Point-of-Purchase to Major Trade Show Product Displays and unique Museum exhibit working modules. Furthermore, TECHCOM offers the best cutaways in the business. For example, our working Model Simulations show off your product and visually represent what is inside. Again, our training aid products are great for classroom teaching, training, or informative demos on the tradeshow floor.

Multi-Media

Highlight your products with powerful visual presentations for marketing, training, and trade shows. Moreover, our Computer Visualization takes your video, print, or media campaign to the next level. In addition, our Interactive services and Virtual Training bring your instructional programs to life. We also provide scriptwriting, graphics, and translation services. Above all, with our computer visualization and training expertise, we offer multiple solutions for your simulation needs.

Publications

Let us interpret complex technology and concepts for your audience with exceptional Technical writing and technical graphics services for print and digital technical publications. Moreover, our technical writers craft basic technical information into helpful print and digital publications.

In addition, TECHCOM has created tens of thousands of illustrations and graphics to demonstrate various components and concepts—for instance, visual representation of internal wiring and electrical systems. Also see Technical Publication Markets.

Be sure to follow us for updates on social media on Facebook, Twitter, and Linkedin.